Vicoustic Flexi Acoustic Panels

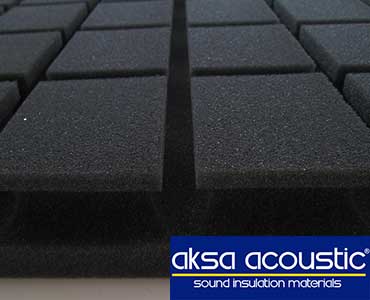

For a crisp and tidy approach to sound deadening, the Acoustic hemisphere foams have a tiled aesthetic for aiding in the reduction of bouncing sonic waves.

Special production can be done but in general sizes are standard. Thickness is not noticeable in sound absorption, but it is more effective than the thicker one. If you want, you can get different colors with different thicknesses.

Usage areas

This sound absorbing Polyurethane foam panel is designed to reduce echo within an environment. The Acoustic Panel Foam enhances the sound quality and aesthetics of any recording or listening environment.

It’s also a great choice for industrial and commercial applications, such as auditoriums, Broadcast Studios, gymnasiums and anywhere else reducing unwanted noise and reverberations is a priority.

Application

Acoustic vicoustic flexi a50 Foams; self-adhesive and non-adhesive in two different models are produced. Self-adhesive acoustic pyramid sponges; the yellow tape on the back of the adhesive surface can be removed and adhered to the surface to be applied. The most important thing to be aware of at this point is; the floor to be applied has a smooth structure. After applying the sponges to the surface to be applied, apply pressure on the acoustic foam; to the surface.

Another model of Acoustic flexi foams: non self-adhesive model can connect to surface with using our special adhesive; solid-based liquid adhesive. After you have turned the adhesive into a container, stick it so that it is not too much to the roller brush and then rub it into the area to which the acoustic panel is applied. We suggest you do not go beyond the size of the panel as you can leave traces. You can apply adhesive to the part by reprinting the material afterwards.

For every kind of questions you can contact us by the phone: +90 216 592 93 16 or you can type to us from contact us page.